When it comes to processing beef brisket in an abattoir, the choice of tools can significantly impact efficiency, safety, and the quality of the final product.

Two primary tools are commonly used: the electric beef brisket saws in Australia and traditional knives comparison is a compelling one. Each has its own set of advantages and drawbacks, and the right choice depends on various factors including the specific needs of your abattoir.

The differences between these different beef-cutting tools is worth exploring if you want to make an informed decision. Electric saws vs knives is a regular topic of conversation in the industry.

Then we will have a section that gives an overall general viewpoint of the importance of knowing the right tool in general when running an abattoir. So let’s get into it!

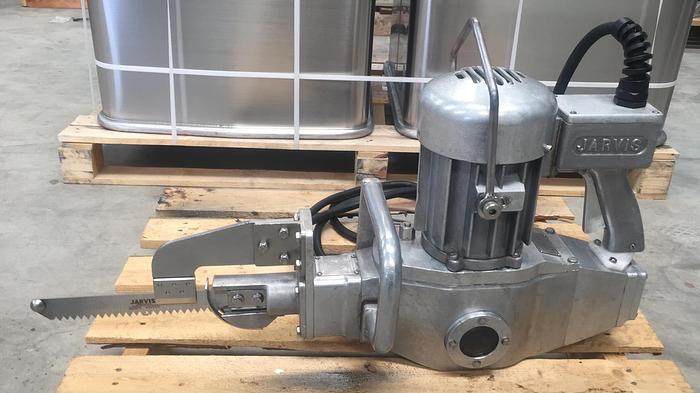

The Electric Beef Brisket Saw

Efficiency and Speed

One of the most significant advantages of using an electric beef brisket saw is its efficiency. These saws are designed to cut through tough meat and bone quickly and with minimal effort.

The motorised blade ensures consistent cuts, reducing the time and labour required for processing. This can be particularly beneficial in high-volume abattoirs where speed is crucial.

Precision and Consistency

Electric saws provide a high level of precision and consistency in cuts. The uniform motion of the blade ensures that each slice is identical, which is essential for maintaining product quality and meeting industry standards.

This consistency can also reduce waste, as there are fewer chances of uneven cuts that might need to be discarded.

Safety Features

Modern electric beef brisket saws come equipped with various safety features to protect operators. These include blade guards, emergency stop buttons, and ergonomic designs that reduce the risk of repetitive strain injuries.

While no tool is entirely risk-free, these features make electric saws a safer option compared to traditional knives when used correctly.

Maintenance and Durability

Electric saws are generally durable and designed to withstand the rigours of daily use in an abattoir. However, they do require regular maintenance to ensure optimal performance.

This includes sharpening or replacing blades, cleaning the saw to prevent contamination, and checking the motor and other components for wear and tear.

Traditional Knives

Versatility and Control

Traditional knives offer a level of versatility and control that electric saws cannot match. Skilled butchers can use knives to make precise cuts that are tailored to the specific requirements of each piece of meat. This flexibility is particularly useful for specialty cuts or when working with smaller quantities of meat.

Cost-Effectiveness

Knives are generally more cost-effective than electric saws, both in terms of initial investment and ongoing maintenance. High-quality knives can last for many years with proper care, and sharpening them is relatively inexpensive. This makes them an attractive option for smaller abattoirs or those with limited budgets.

Skill and Training

Using traditional knives effectively requires a high level of skill and training. Butchers must be trained to make precise cuts quickly and safely, which can take time and practice. However, once these skills are mastered, knives can be incredibly efficient tools.

Safety Considerations

While knives do not have the same built-in safety features as electric saws, proper training and the use of protective equipment can mitigate many risks. It is essential to ensure that all staff are trained in safe knife handling techniques and that they use cut-resistant gloves and other protective gear.

Electric Saws vs Traditional Knives: A Comparison

Speed and Efficiency

Electric saws are generally faster and more efficient than traditional knives, making them ideal for high-volume operations.

The motorised blade can cut through meat and bone quickly, reducing the time and effort required for processing. In contrast, knives rely on the skill and strength of the operator, which can be more time-consuming.

Precision and Consistency

Electric saws offer greater precision and consistency in cuts, which is crucial for maintaining product quality. The uniform motion of the blade ensures that each slice is identical, reducing waste and ensuring that the final product meets industry standards.

Knives, on the other hand, require a skilled operator to achieve the same level of precision.

Safety

Both tools have safety considerations, but electric saws come with built-in safety features that can reduce the risk of accidents.

However, they also require regular maintenance to ensure these features remain effective. Knives, while lacking these features, can be used safely with proper training and protective equipment.

Cost

Knives are generally more cost-effective than electric saws, both in terms of initial investment and ongoing maintenance. However, the increased efficiency and consistency of electric saws can offset these costs in high-volume operations.

Versatility

Knives offer greater versatility and control, allowing butchers to make precise cuts tailored to specific requirements. This makes them ideal for specialty cuts or smaller quantities of meat. Electric saws, while efficient, are less flexible and may not be suitable for all types of cuts.

The Importance of Understanding What to Use in Each Area of Your Abattoir

Running an abattoir efficiently and humanely requires a thorough understanding of the tools at your disposal.

The right equipment not only ensures the quality of the meat but also enhances safety and productivity.

Here’s why knowing the right tools for the job is crucial in an abattoir setting.

Efficiency and Productivity

Using the correct tools can significantly boost efficiency. For instance, motorised equipment designed to cut through tough meat and bone quickly can reduce the time and effort required for processing.

This is particularly important in high-volume abattoirs where speed is essential. In contrast, manual tools, while versatile, may not match the speed and consistency of motorised equipment, especially for large-scale operations.

Precision and Consistency

Precision is key in meat processing. Tools that provide consistent cuts are vital for maintaining product quality.

Uniform slices ensure that the meat meets industry standards and reduces waste.

While skilled workers can achieve precise cuts with manual tools, the consistency offered by motorised equipment is unmatched. This consistency is crucial for both the aesthetic and practical aspects of meat processing.

Safety

Safety is a major concern in any abattoir. Modern equipment often comes equipped with safety features such as blade guards and emergency stop buttons, which help protect operators from accidents.

While manual tools are essential, they require proper training and protective equipment to be used safely. Understanding the safety features and proper handling of every section and what machinery and tools are in use can prevent injuries and ensure a safer working environment.

Plus overall Personal Protective Equipment (PPE) must be researched for each part of the abattoir so workers have sufficient protection regardless of what job they are doing.

Cost-Effectiveness

Choosing the right tools can also impact the cost-effectiveness of your operations. While motorised equipment may have a higher initial cost, its efficiency and durability can lead to long-term savings.

It reduces the time and labour needed for processing, which can offset the initial investment. On the other hand, manual tools are more affordable upfront and can be cost-effective for smaller operations or specific tasks.

Balancing the cost and benefits of each tool is essential for managing expenses effectively.

Versatility

Different tools offer varying levels of versatility. Manual tools are incredibly versatile and can be used for a wide range of tasks, from skinning to boning. They allow workers to make precise, tailored cuts, which is essential for specialty products.

However, motorised equipment, designed for specific tasks, excels in those areas. Knowing when to use each tool can enhance the versatility and efficiency of your operations.

Compliance with Regulations

Abattoirs must comply with strict regulations regarding animal welfare and meat processing. Using the right tools ensures that these standards are met.

For example, motorised equipment can provide quick and humane cuts, reducing stress and pain for the animals. This compliance is not only a legal requirement but also an ethical obligation that can enhance the reputation of your abattoir.

Training and Skill Development

Understanding the tools used in an abattoir is also crucial for training and skill development. Staff must be trained to use both motorised and manual tools effectively.

This training ensures that they can operate the equipment safely and efficiently, which is essential for maintaining high standards of meat processing.

Investing in training programs can improve the overall performance of your team and the quality of the products.

SUMMARY

Knowing the right tools for the job is essential for running an efficient, safe, and compliant abattoir. Whether it’s the speed and precision of motorised equipment or the versatility of manual tools, each has its place in the processing line. By understanding the strengths and limitations of each tool, abattoir operators can enhance productivity, ensure safety, and maintain high standards of meat quality.