Introduction to Galvanized Zinc Paint

Galvanized zinc paint, often referred to as cold galvanizing compound, is a type of coating used to protect metal surfaces from corrosion. It consists primarily of zinc, which provides a protective barrier to prevent rust and degradation of the underlying metal. This type of paint is especially popular in industrial and commercial settings where metal structures are exposed to harsh environmental conditions.

Benefits of Galvanized Zinc Paint

-

Corrosion Resistance: The primary advantage of galvanized zinc paint is its ability to resist corrosion. Zinc acts as a sacrificial anode, meaning it will corrode before the underlying metal does, thereby protecting the metal from rust and oxidation.

-

Durability: Zinc paint forms a tough, abrasion-resistant coating that can withstand physical impacts and harsh weather conditions. This makes it ideal for outdoor structures such as bridges, fences, and pipelines.

-

Cost-Effective: Compared to hot-dip galvanizing, where metal is dipped into molten zinc, using galvanized zinc paint is more economical and easier to apply, especially for large or immovable structures.

-

Easy Application: Galvanized zinc paint can be applied using a brush, roller, or spray. This flexibility allows for easy application on various surfaces and shapes, ensuring comprehensive coverage.

-

Repair and Maintenance: It is also used for repairing galvanized surfaces that have been damaged or have started to corrode. This ensures the longevity of the protective layer without the need for expensive and labor-intensive repairs.

If you want to know more information about aerosol spray paint suppliers visit Revo Paint.

Applications of Galvanized Zinc Paint

Galvanized zinc paint is used in various industries and applications, including:

-

Construction: It is widely used to protect structural steel in buildings, bridges, and other infrastructures from corrosion.

-

Marine: Ships, docks, and offshore platforms are exposed to saltwater, which is highly corrosive. Zinc paint helps protect these structures from rust.

-

Automotive: Parts of vehicles, especially those exposed to the elements, are often coated with zinc paint to prevent rusting.

-

Agriculture: Farm equipment and machinery are frequently exposed to moisture and chemicals, making zinc paint a valuable protective measure.

-

Industrial Equipment: Tanks, pipes, and other industrial equipment benefit from the protective properties of galvanized zinc paint.

Types of Galvanized Zinc Paint

-

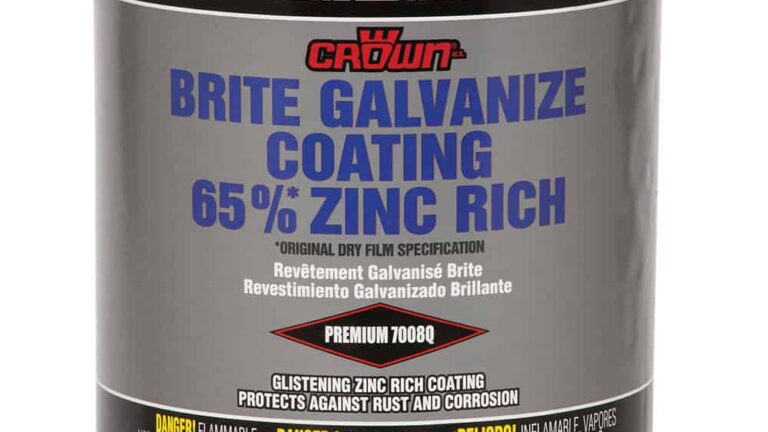

Cold Galvanizing Compound: This is the most common type, consisting of a high percentage of zinc dust mixed with a binder. It provides excellent protection against corrosion.

-

Zinc-Rich Primers: These are used as a base coat to protect metal surfaces and can be top-coated with other paints for additional protection and aesthetic purposes.

-

Epoxy Zinc Paint: Combining the properties of epoxy and zinc, this type offers superior adhesion, chemical resistance, and durability.

How to Apply Galvanized Zinc Paint

-

Surface Preparation: The surface must be clean, dry, and free from rust, oil, and other contaminants. Sandblasting or wire brushing can help achieve the desired surface condition.

-

Application Method: Depending on the size and shape of the surface, choose the appropriate application method—brush, roller, or spray.

-

Coating Thickness: Apply the paint to the recommended thickness, usually specified by the manufacturer, to ensure optimal protection.

-

Curing Time: Allow sufficient curing time for the paint to dry and form a hard, protective layer. This can vary depending on the type of paint and environmental conditions.

Aerosol Spray Paint Suppliers

Aerosol spray paints are convenient and easy-to-use alternatives for smaller projects or hard-to-reach areas. They come in various formulations, including those with zinc for galvanizing purposes. Here are some top aerosol spray paint suppliers:

-

Rust-Oleum: Known for its high-quality protective paints, Rust-Oleum offers a range of zinc-rich aerosol spray paints designed for touch-up and small-scale projects.

-

Krylon: Another leading brand, Krylon, provides durable and effective spray paints, including those suitable for galvanizing metal surfaces.

-

ZRC Worldwide: Specializing in zinc coatings, ZRC Worldwide offers aerosol spray paints with high zinc content for superior corrosion protection.

-

CRC Industries: CRC produces a variety of industrial-grade aerosol spray paints, including zinc-rich options for effective rust prevention.

-

Belzona: Belzona’s range of aerosol spray paints includes options specifically designed for metal protection and corrosion resistance.

Choosing the Right Supplier

When selecting an aerosol spray paint supplier, consider the following factors:

-

Product Quality: Look for products with high zinc content and proven effectiveness in corrosion protection.

-

Brand Reputation: Choose suppliers with a strong reputation for quality and reliability in the industry.

-

Availability: Ensure the supplier has a wide distribution network so you can easily access their products.

-

Customer Support: Good customer support can assist with product selection and application guidance, ensuring you get the best results.

-

Price: Compare prices among different suppliers to find a cost-effective option that meets your needs.

Conclusion

Galvanized zinc paint is an essential tool for protecting metal surfaces from corrosion and extending their lifespan. Its versatility, ease of application, and cost-effectiveness make it a popular choice across various industries. Additionally, aerosol spray paints provide a convenient solution for smaller projects or touch-ups. By choosing reputable suppliers and following proper application techniques, you can ensure the best protection for your metal structures and equipment. Whether you are working on a large construction project or a small DIY task, galvanized zinc paint offers reliable and long-lasting protection against the elements.